Introduction

Screw Air Compressors are commonly used in all types of industries. A screw compressor works with an electric motor and a male and female rotor that rotate in the opposite direction. This efficient compression process results in continuous and consistent airflow delivery, which is critical for various industries where uninterrupted compressed air is a necessity. Efficiency of the Electric motor defines the energy consumption. Energy efficient compressors are always a key factor in sales.

Fix Speed Rotary Motors

As its name clearly indicates, a fixed-speed air compressor operates by supplying a consistent or fixed voltage and frequency to its motor, which in turn drives its rotary screws at a consistent speed to draw in and pressurize air. If your plant operates on a 24/7 basis without significant fluctuations in production cycles, then your energy consumption may be fairly consistent and a fixed-speed air compressor might be a good choice.

If, however, your facility goes through daily, weekly, or even seasonal changes to its production outputs—and subsequently has varying levels of air demands—then a fixed-speed air compressor will end up using more energy and be somewhat wasteful over the course of its life cycle [https://kaishanusa.com/].

Variable Speed Rotary Motors

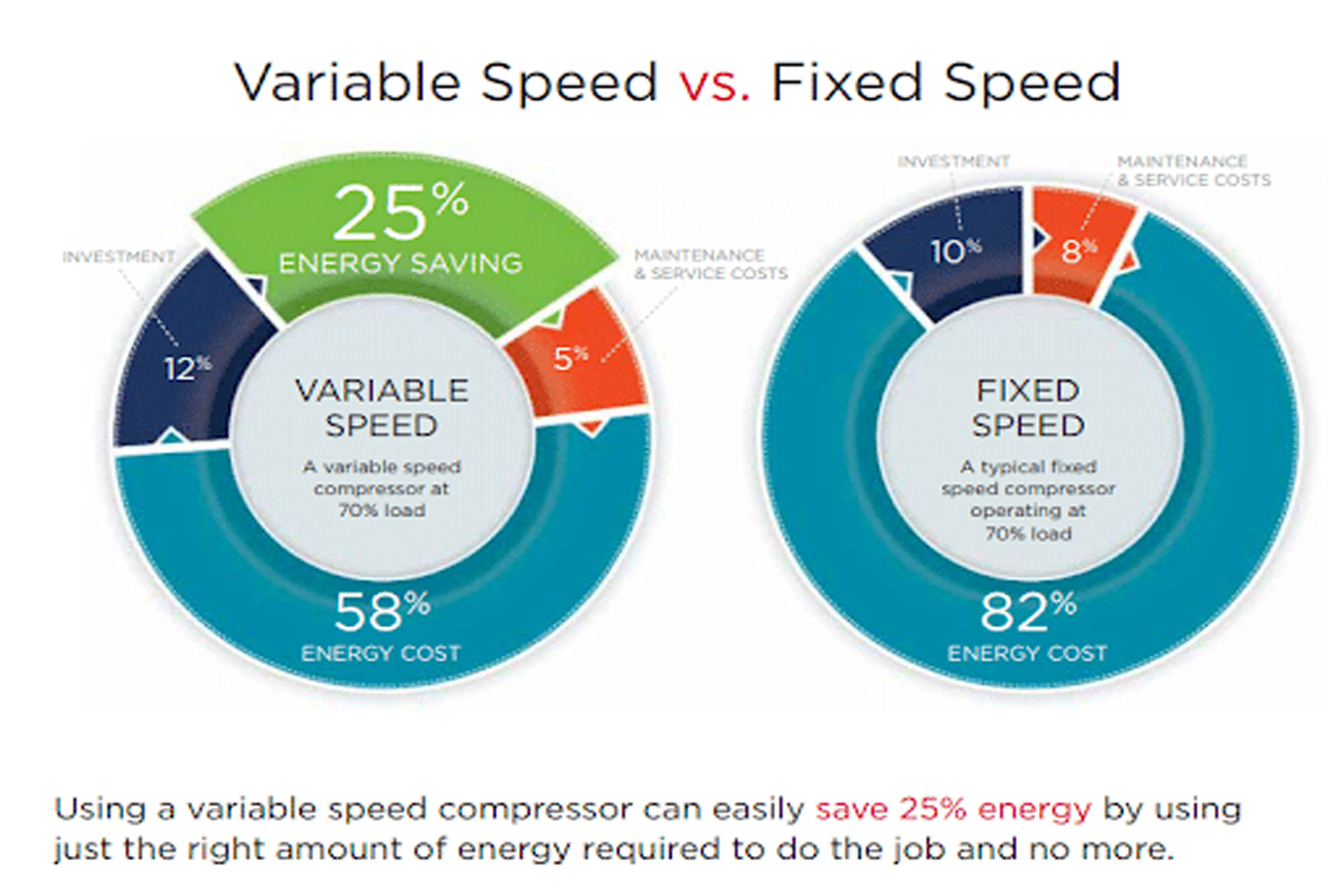

In contrast, a Variable Speed Drive (VSD) air compressor can operate anywhere in the range between its minimum and maximum speed, and it automatically adjusts the speed so production of compressed air matches demand in real time. When demand increases, the motor speeds up. When demand decreases, the motor slows down. This capability saves energy because the compressor doesn’t have to run flat out whenever it’s on. You can think of VSD like the accelerator in a car, which allows you to vary the car’s speed according to road conditions, level of traffic and whether you’re in a hurry! [https://www.atlascopco.com/]

Advantages and Disadvantages

No. | Fixed Speed | Variable Speed |

1 | Flat Run Fixed speed runs on the specified speed and keeps consuming power at contact rate. [https://www.atlascopco.com] | Energy Efficient Variable speed machines have special design. They reduce/increase speed depending on the consumption. [https://www.atlascopco.com] |

2 | Initial Cost Fixed speed machines are conventional, where initial cost is less. [https://www.atlascopco.com] | Initial Cost Variable speed involve inverter to control speed which leads to higher initial cost, however they recover initial cost over the period of time due to less power consumption. [https://www.atlascopco.com] |

3 | Pressure Band Fixed speed compressor does not have capability to work in tighter pressure band. [https://www.atlascopco.com] | Pressure Band Variable speed compressors are designed to work efficiently in much tighter pressure band, due to speed variable faculty. [https://www.atlascopco.com] |

4 | Minimum Working Pressure Fixed speed compressor does not maintain the minimum working pressure. [https://www.atlascopco.com] | Minimum Working Pressure A VSD compressor can operate at lower delivery pressures and still maintain the air system’s required minimum working pressure. VSD also delivers more consistent discharge pressure for all the compressed air applications throughout your facility. [https://www.atlascopco.com] |

5 | Unloading Pressure Fixed speed compressor must have an unloading pressure set, where the compressor will start again to maintain working pressure, This process cause a torque load on power that effect cost factor. [https://www.atlascopco.com] | Unloading Pressure Unlike fixed speed compressor VSD compressor have no set unloading working pressure. They can reduce pressure as low as the demand can go. [https://www.atlascopco.com] |

6 | Energy Saving on Pressure Fixed speed does not work below unloading pressure set, So minimum energy consumption is much higher. [https://www.atlascopco.com] | Energy Saving on Pressure Since there is no minimum pressure is set for VSD compressors. Each 1 Bar down save 7% of the energy consumption. [https://www.atlascopco.com] |

7 | Conventional Three Phase Motor Fixed machine mostly use conventional three phase induction motor, where they have less benefits. 1. Increased maintenance on increased start/stop per hour 2. Single cooling system. 3. Much higher noise 4. Geared/Belt Connection 5. Lesser control over PLCs | Permanent Magnet Motor Latest VSD machines mostly come with PM motors which have standalone benefits, For Example. 1. Unlimited Motor Start/Stop per hour 2. Dual cooling system 3. Low Noise 4. Direct Connection (No Gearing) 5. Easy to maintain 6. Easy to maintain full-function controller. [https://www.industrialair.co.nz/] |

8 | Starting Current Fixed machines have much higher current consumption on start, sometimes more than a double of the capacity of the motor. High Starting current may cause power line issues. | Starting Current In-comparison to fixed speed VSDs does not have any starting current surge. They work smoothly and increase current as per demand. As a result VSDs have fower power line issues. [https://www.ceccato.com] |

9 | Components Life Cycle Fixed Speed and load/unload function can cause a shorter life cycle of the attached components. [https://www.ceccato.com] | Components Life Cycle Variable speed and soft start feature result in longer life cycle of attached components. [https://www.ceccato.com] |

We at Air Power Services offer both VSD and fixed speed compressors from the wide variety world’s top manufacturers. Each type offer advantages in specific circumstances. For example, a fixed speed compressor is a smart choice when the demand for air is essentially constant. A factory running 24/7 with automated equipment that consumes compressed air at a predictable and uniform rate is a good application for a fixed-speed compressor. A VSD compressor is a smart choice when demand for air varies by process, time of day, shift or time of the year, when demand fluctuates. [https://www.atlascopco.com]

Conclusion

Since the dawn of the 21st century, a new awareness has taken hold of the industrial sector. The old school age when manufacturers were happy just to maximize profits with the lowest possible overhead — today, all companies that thrive make eco-friendliness a central tenet of brand identity. As part of that goal, innovations in compressed-air technology have made the variable speed-driven air compressor into an industry standard among companies around the world. With one innovation after another.[https://www.quincycompressor.com]

For a wide range of applications, the finest compressed-air systems are those that run on variable speed drives. Not only do VSD-driven units offer some of the greatest longevity and energy efficiency, but they also adjust to the variable speed and torque requirements of each application. [https://www.quincycompressor.com]